AccuSense

EASY OF USE

AccuSense® gives First Responders the power of a laboratory-grade, gaseous chemical detection system in a field-portable unit. It’s like having the entire GC lab and technicians with you in a simple to use one button system. It is the perfect portable device for the detection, identification, and quantification of Toxic Industrial Chemicals (TICs).

DUAL-HYPHENATED GAS CHROMATOGRAPHY (DHGC)

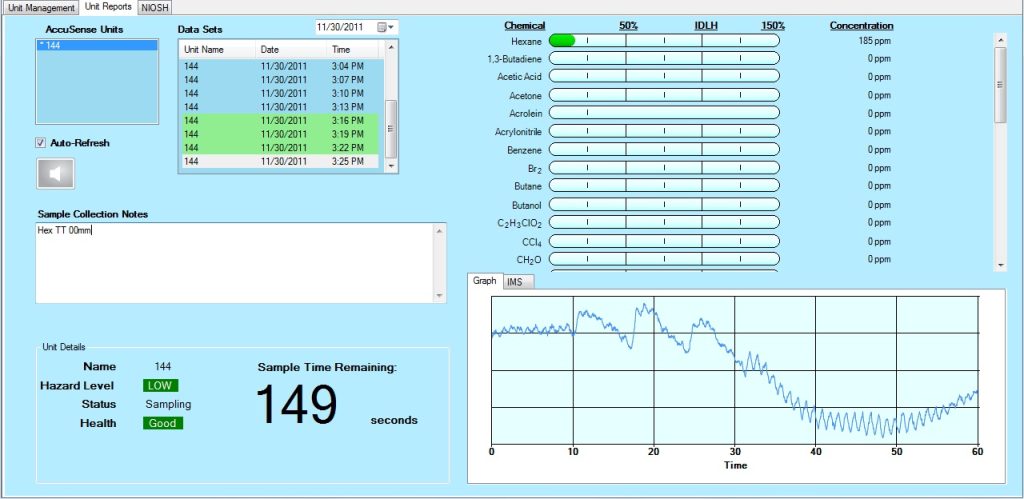

AccuSense uses Dual-Hyphenated Gas Chromatography (DHGC) technology for the separation of chemicals and a proprietary thermal detection system to display concentration levels of multiple chemicals simultaneously. The chemicals and concentration levels are displayed via wireless links to a laptop computer. Identified chemicals and concentrations are automatically displayed relative to published IDLH (Immediately Dangerous to Life and Health) values and displayed on the screen for decision analysis.

CONTINUOUS OPERATION

Typical GC-based solutions require the use of an inert elute gas, such as argon or nitrogen. Products which rely on these “consumables” cannot be deployed for continuous field operations or hazardous areas where humans should not be exposed.

AccuSense solves the “consumables” problem by using internally conditioned ambient air as its elute gas source. This results in uncompromised continuous operation capabilities and lack of human intervention during unit deployment.

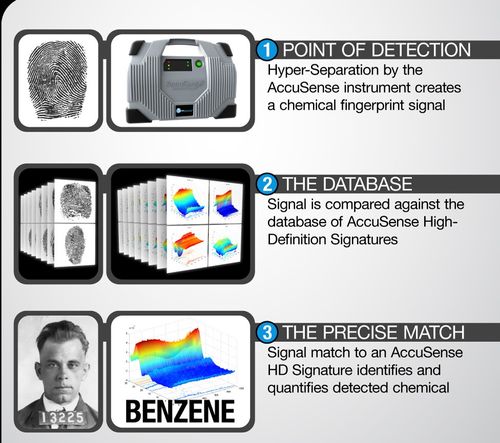

PROVIDES A 3D “FINGERPRINT”

Each AccuSense chemical signature is a three dimensional “fingerprint” that is highly distinguishable from all other chemicals and from “confuser” chemicals which create “false positives/negatives.” The patented detection and identification systems of AccuSense are a technology breakthrough for the industry, giving superior accuracy compared to competitive products and solutions.

RELIABLE AND COST SAVING

In the chemical detection business, it is critical to detect, identify, and in the case of AccuSense, provide the concentration levels of the chemicals present. All of this information needs to be provided without the appearance of false positives or false negatives. A false positive is a case in which a device indicates that a chemical is present when in fact it is not, while a false negative is a case in which a devices indicates that no chemicals are present when in fact they are. Unnecessary response to chemical detectors that are reporting false positives is costly and time-consuming, adding to the overall cost of the instruments. The cost of a false-positive reading in an area such as an airport or convention center can be extremely costly due to the unnecessary evacuation of the public and deployment of a HAZMAT team. Continual response to false-positives is unacceptable and the ability of AccuSense to distinguish between chemicals of interest and confusers will significantly limit the cost of unnecessary response actions.

PERFORMANCE VALIDATION

SEER has created a unique state-of-the-art chemical separation and classification algorithm based partly on an artificial neural network algorithm. Because the neural network is trained only on known valid chemical signatures validated against an Agilent™ mass spectrometer, it is inherently robust with respect to false positives.

Part of the performance validation software runs all possible chemical combinations on the Cray™ supercomputer and produces a performance map which indicates exactly how the unit will respond.

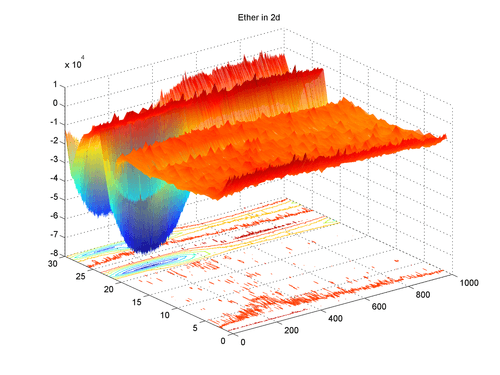

SEER “PICASSO”

The SEER “Picasso” is actually a 3D surface plot produced with Matlab™ scientific software on the Cray™ supercomputer. It is used as a quick visual check of the performance of a trained neural network chemical separation algorithm.

Also, a user does not need to worry about whether false positives will occur with any particular set of chemicals. Part of the performance validation software runs all possible chemical combinations on our supercomputer and produces a performance map which indicates the exact performance of the algorithm.

SOFTWARE " SEERID "

The SEER “Picasso” is actually a 3D surface plot produced with Matlab™ scientific software on the Cray™ supercomputer. It is used as a quick visual check of the performance of a trained neural network chemical separation algorithm.

Also, a user does not need to worry about whether false positives will occur with any particular set of chemicals. Part of the performance validation software runs all possible chemical combinations on our supercomputer and produces a performance map which indicates the exact performance of the algorithm.